Chapter 8 Manufacturing Industries

Textbook Questions Solved

1. Choose the right answers of the following from the given options:

Question 1.(i)

Which is not a factor of industrial location?

(a) Market

(b) Capital

(c) Population Density

(d) Power

Answer:

(c) Population Density

Question 1.(ii)

The earliest Iron and Steel Company to be established in India was:

(a) IISCO

(b) TISCO

(c) Visvesvaraiya Iron and Steel Works

(d) Mysore Iron and Steel Works

Answer:

(b) TISCO

Question 1.(iii)

The first modern cotton mill was established in Mumbai because:

(a) Mumbai is a port

(b) It is located near cotton growing area

(c) Mumbai was the financial centre

(d) All of the above.

Answer:

(d) All of the above.

Question 1.(iv)

The nucleus of the Hugli Industrial Region is:

(a) Kolkata-Haora (Howrah)

(b) Kolkata-Rishra

(c) Kolkata-Medinipur

(d) Kolkata-Konnagar

Answer:

(a) Kolkata-Haora (Howrah)

Question 1.(v)

Which one of the following is the second largest producer of sugar:

(a) Maharashtra

(b) Uttar Pradesh

(c) Punjab

(d) Tamil Nadu

Answer:

(b) Uttar Pradesh

2. Answer the following questions in about 30 words:

Question 2.(i)

Why do you think that the iron and steel industry is basic to the industrial development of any country?

Answer:

Iron and steel are basic to economic development of any country because they are the basic raw material for production of all other goods- both industrial and commercial. All other industries are based on the products manufactured from these industries. Until and unless iron and steel are produced, even a nail, which is basic to all constructions, cannot be manufactured.

Question 2.(ii)

Name the two sectors of the cottage textile industries. How are they different?

Answer:

The cotton textile industry in India can be broadly divided into two sectors, the organised sector and the unorganised sector. The decentralised sector includes cloth ‘ produced in handlooms (including Khadi) and powerlooms. The production of the organised sector has drastically fallen from 81 per cent in the mid-twentieth century to only about 6 per cent in 2000. At present, the powerlooms on the decentralised sector produce more than the handloom sector.

Question 2.(iii)

Why is the sugar industry a seasonal industry?

Answer:

Sugar industry is totally based on sugarcane as raw material. Sugarcane is a seasonal crop harvested annually. Since sugarcane is a perishable crop and its sucrose content starts to decline within 24 hours only, therefore sugarcane cannot be stored for production of sugar later in the year. As a result production of sugar is limited to only harvesting time of the sugarcane.

Question 2.(iv)

What is the raw material base for the petrochemical industry? Name some of the products of this industry.

Answer:

Crude petroleum is the raw material for the petroleum industry. It is refined to obtain various products, which collectively are referred to as petrochemical industries.This group of industries is divided into four sub-groups:

- polymers,

- synthetic fibres,

- elastomers, and

- surfactant intermediate.

Question 2.(v)

What is the major impact of Information Technology (IT) revolution in India?

Answer:

The advancement in information technology has had a profound influence on the country’s economy. The Information Technology (IT) revolution opened up new possibilities of economic and social transformation. The IT and IT enabled business process outsourcing (ITES- BPO) services continue to be on a robust growth path. Indian software industry has emerged as one of the fastest growing sectors in the economy. The software industry has surpassed electronic hardware production. The Indian government has created a number of software parks in the country. Also it has a large number of females employed in it.

3. Answer the following questions in about 150 words:

Question 3.(i)

How did the Swadeshi movement give a major impetus to the cotton textiles industry?

Answer:

Swadeshi movement was the movement, which was started by Gandhiji as a step towards achieving self-sufficiency in production. British goods were boycotted and Indian manufactured products were promoted. British in India deepened their roots by destroying indigenous industries. Swadeshi hit on this very policy of the government. People destroyed foreign manufactured goods in huge quantities; they started spinning for their own clothes. Capital was collected and new mills were setup throughout the country under the impetus provided by the swadeshi movement. New mills, which are still functioning, sprang up throughout the country. Khadi cloth and khadi industry were revived, the traditional artisans who have lost their livelihood were reabsorbed under the swadeshi economy as a movement against the British led economy. Not only large-scale industries were set up but also small and cottage industry was revived. Since under the wave nationalism people were adopting khadi- Indian handloom, the demand for the Indian cotton shot up, hence the entire indigenous cotton industry of India was revived. It also helped in generating employment opportunities leading to overall growth in national income.

Question 3.(ii)

What do you understand by liberalisation, privatisation and globalisation? How have they helped industrial development in India?

Answer:

The New Industrial Policy was announced in 1991. The major objectives of this policy were to build on the gains already made, correct the distortions or weaknesses that have crept in, maintain a sustained growth in productivity and gainful employment and attain international competitiveness. Within this policy, measures initiated are:

- abolition of industrial licensing,

- free entry to foreign technology,

- foreign investment policy,

- access to capital market,

- open trade,

- abolition of phased manufacturing programme, and

- liberalized industrial location programme. The policy has three main dimensions: liberalization, privatisationand globalization.

The industrial licensing system has been abolished for all except six industries related to security, strategic or environmental concerns. At the same time, the number of industries reserved for public sector since 1956 have been reduced from 17 to 4. Industries related to atomic energy, substances specified in the Schedule of the Department of Atomic Energy as well as Railways have remained under the public sector. The government also has decided to offer a part of the shareholdings in the public enterprises to financial institutions, general public and workers. The threshold limits of assets have been scrapped and no industiy requires prior approval for investing in the delicensed sector. They only need to submit a memorandum in the prescribed format.

In the new industrial policy, Foreign Direct Investment (FDI) has been seen as a supplement to the domestic investment for achieving a higher level of economic development. FDI benefits the domestic industry as well as the consumers by providing technological upgradation, access to global managerial skills and practices, optimum use of natural and human resources, etc. Keeping all this in mind, foreign investment has been liberalized and the government has permitted access to an automatic route for Foreign Direct Investment. The government has also announced changes in the industrial location policies. Industries are discouraged in or very close to large cities due to environmental reasons.

The industrial policy has been liberalized to attract private investor both domestic and multi-nationals. New sectors like, mining, telecommunications, highway construction and management have been thrown open to private companies. Globalization means integrating the economy of the country with the world economy. Under this process, goods and services along with capital, labour and resources can move freely from one nation to another. The thrust of globalisation has been to increase the domestic and external competition through extensive application of market mechanism and facilitating dynamic relationship with the foreign investors and suppliers of technology. In Indian context, this implies:

- opening of the economy to foreign direct investment by providing facilities to foreign companies to invest in different fields of economies activity in India;

- removing restrictions and obstacles to the entry of multi-national companies in India;

- allowing Indian companies to enter into foreign collaboration in India and also encouraging them to set up joint ventures abroad;

- carrying out massive import liberalization programmes by switching over from quantitative restrictions to tariffs in the first place, and then bringing down the level of import duties considerably; and

- instead of a set of export incentives, opting for exchange rate adjustments for promoting export.

A breakup of foreign collaboration approval reveals that the major share went to core, priority sectors while infrastructural sector was untouched. Further, gap between developed and developing states has become wider. Major share of both domestic investment as well as foreign direct investment went to already developed states. Uttar Pradesh, the state with the largest population has only 8 per cent. In spite of several concessions, seven north-eastern states could get less than 1 per cent of the proposed investment. In fact, economically weaker states could not compete with the developed states in open market in attracting industrial investment proposals and hence they are likely to suffer from these processes.

Extra Questions

Very Short Answer Type Questions

Question 1.

Why manufacturing is significant?

Answer:

Manufacturing industries provide employment to a large number of people either directly or indirectly and as well as contribute significantly to the national economy. They provide us with all the manufactured goods for our use.

Question 2.

For which industries market plays an important role for their location.

Answer:

Cotton textiles and petroleum based industries.

Question 3.

Which state has the largest number of cotton mills?

Answer:

Tamil Nadu.

Question 4.

Where and when was the first cotton mill set up?

Answer:

In Mumbai, 1854.

Question 5.

Which is the 2nd most important agro- based industry in India?

Answer:

Sugar industry.

Question 6.

Which state is the largest producer of sugar?

Answer:

Maharashtra.

Question 7.

What is the contribution of IT industry towards India’s GDP?

Answer:

The IT software and services industry account for almost 2 per cent of India’s GDP.

Question 8.

When was the new Industrial policy undertaken?

Answer:

The new Industrial policy was undertaken in 1991.

Question 9.

How many Major Industrial Region are there?

OR

Name the important industrial regions of India.

Answer:

There are eight major Industrial Regions:

- Mumbai-Pune Region,

- Hugh Region,

- Bengaluru-Tamil Nadu Region,

- Gujarat Region,

- Chotanagpur Region,

- Vishakhapatnam-Guntur Region,

- Gurgaon-Delhi-Meerut Region, and

- Kollam-Thiruvananthapuram Region.

Question 10.

Chhotanagpur Industrial belt primarily occupies which states?

Answer:

Jharkhand, parts of Odisha and West Bengal.

Question 11.

What is manufacturing?

Answer:

Manufacturing refers to mass production of all/any kinds of identical goods with the use of power, specialized labour and a factory. It transforms raw materials into finished goods of high value. It is done in either by hand or power driven machinery.

Question 12.

Classify industries on the basis of size.

Answer:

On the basis of size industries are of three types:

- Cottage industries (Household Industries)

- Medium scale industries

- Large scale industries

Question 13.

Classify industries on the basis of ownership.

Answer:

On the basis of ownership, industries are of three types:

- Private sector industry

- Public sector industry

- Joint sector industry and cooperative sector

Question 14.

Classify industries on the basis of product.

- Basic industry

- Capital-goods industries

- Consumer goods industries

- Intermediate goods industries

Question 15.

Classify industries on the basis of the use of their products.

Answer:

On the basis of the use of their products industries are classified as:

- Basic goods industries

- Capital goods industries

- Intermediate goods industries

- Consumer goods industries.

Question 16.

When and with whose collaboration was Rourkela Steel Plant established?

Answer:

The Rourkela Steel plant was set up in 1959 in the Sundargarh district of Odisha in collaboration with Germany.

Question 17.

When and with whose collaboration was Bhilai Steel Plant established?

Answer:

The Bhilai Steel Plant was established with Russian collaboration in Durg district of Chhattisgarh and started production in 1959.

Question 18.

Which industries are included in traditional industries?

Answer:

Iron and steel industry, cotton industry and sugar industry are considered as traditional industries.

Question 19.

Why are petrochemical industries and IT industry considered as modern industries?

Answer:

These industries are considered as the most modern industries because they make use of latest modern technology machinery and computerized methodology.

Question 20.

Who started the first naphtha based chemical industry?

OR

Name the first Naptha based chemical industries.

Answer:

The National Organic Chemical Industries Limited (NOCIL) established in private sector in 1961, started the first naphtha-based chemical industry in Mumbai.

Question 21.

What was the impact of the policy of dereservation in 1991?

Answer:

The number of industries reserved for public sector since 1956 have been reduced from 17 to 4. Industries related to atomic energy, substances specified in the Schedule of the Department of Atomic Energy as well as Railways have remained under the public sector.

Question 22.

Which sectors have received the highest FDI in India?

Answer:

In India larger parts of this investment have gone to domestic appliances, finance, services, electronics and electrical equipment, and food and dairy products.

Question 23.

Name the raw materials essential for iron and steel industry. Why should they be located near the source of its raw materials?

Answer:

The raw materials essential for Iron and Steel Industry are iron-ore, coking coal, limestone, dolomite, manganese and fire clay. Because all these raw materials are weight losing, therefore, the Iron and Steel industry should be located near the source of raw materials.

Question 24.

Iron and steel industry is only in public sector. Why?

Answer:

Because no investor is willing to invest in the heavy and bulky industries as the capital is huge and benefit is incurred in a long span of time.

Question 25.

What does TISCO stand for?

Answer:

Tata Iron and Steel Company.

Question 26.

What does IISCO stand for?

Answer:

Indian Iron and Steel Company.

Question 27.

Name the new steel plants that were set up in fourth plan period. How are they different from earlier ones?

Answer:

Vizag Steel Plant, Vijaynagar Steel Plant & Salem Steel Plant. Paradip is the latest and new steel plant is under construction in Odisha. They are different from the earlier ones as they are away from the main raw material sources.

Question 28.

Which city is referred to as the petrochemical industry?

Answer:

The city of Mumbai is referred to as the petrochemical industiy.

Question 29.

Name .the important petrochemical centres of India.

Answer:

Important centres include:

- Auraiya (UP)

- Jamnagar, Gandhinagar and Hajira (Gujarat)

- Nagothane, Ratnagiri (Maharashtra)

- Haldia (West Bengal)

- Vishakhapatnam (Andhra Pradesh)

Question 30.

What are polymers made from?

Answer:

Polymers are made from ethylene propylene.

Question 31.

Name the important minor industrial regions of India.

Answer:

Minor industrial regions of India are:

- Ambala-Amritsar

- Saharanpur-Muzaffarnagar-Bijnor

- Indore-Dewas-Ujjain

- Jaipur-Ajmer

- Kolhapur-South Kannada

- Northern Malabar

- Middle Malabar

- Adilabad-Nizamabad

- Allahabad-Varanasi-Mirzapur

- Bhojpur-Munger

- Durg-Raipur

- Bilaspur-Korba

- Brahmaputra valley

Question 32.

Name the important industrial districts of India.

Answer:

Important industrial districts of India are:

- Kanpur

- Agra

- Gwalior

- Lucknow

- Cuttack

- Aligarh

- Purnia

- Bareilly

- Hyderabad

- Nagpur

- Bhopal

- Jalpaiguri

- Gorakhpur

- Kota

- Jabalpur

Short Answer Type Questions

Question 1.

List the significance of the secondary sector.

Answer:

Secondary sector processes primary products into finished goods of higher value. It provides employment to a large number of people and contributes to national income.

Question 2.

Why are synthetic fibres gaining importance? Name some locations where they are located.

Answer:

Synthetic fibres are widely used in the manufacturing of fabrics because of their inherent strength, durability, washability, and resistance to shrinkage. Industries manufacturing nylon and polyester yarns are located at Kota, Pimpri, Mumbai, Modinagar, Pune, Ujjain, Nagpur and Udhna. Acrylic staple fibre is manufactured at Kota and Vadodara.

Question 3.

What is knowledge based industry? Why is it gaining importance? ‘

Answer:

The advancement in information technology has had a profound influence on the country’s economy. The Information Technology (IT) revolution opened up new possibilities of economic and social transformation. The IT and IT enabled business process outsourcing (ITES-BPO) services continue to be on a robust growth path. Indian software industry has emerged as one of the fastest growing sectors in the economy.

Questions 4.

What is the impact of globalisation in India?

OR

What do you mean by globalisation in Indian context?

Answer:

The impact of globalization in India are:

- Opening of the economy to foreign direct investment by providing facilities to foreign companies to invest in different fields of economic activity in India.

- Removing restrictions and obstacles to the entry of multinational companies in India.

- Allowing Indian companies to enter into foreign collaboration in India and also encouraging them to set up joint venture’s abroad.

- Carrying out massive import liberalization programmes by switching over from quantitative restrictions to tariffs in the first place, and then bringing down the level of import duties considerably.

- Instead of a set of export incentives, opting for exchange rate adjustments for promoting export.

Question 5.

Why there is spatial variation in FDI in India?

Answer:

Major share of both domestic investment as well as foreign direct investment went to already developed states. For example, out of the total proposed investment by the industrial entrepreneurs during 1991-2000 nearly one fourth (23 per cent) was for industrially developed Maharashtra, 17 per cent for Gujarat, 7 per cent for Andhra Pradesh, and about 6 per cent for Tamil Nadu while Uttar Pradesh, the state with the largest population has only 8 per cent. In spite of several concessions, seven north-eastern states could get less than 1 per cent of the proposed investment. In fact, economically weaker states could not compete with the developed states in open market in attracting industrial investment proposals and hence they are likely to suffer from these processes.

Question 6.

How are industrial regions distributed in our country? List the indices used to identity them.

Answer:

Industries are not evenly distributed in the country. They tend to concentrate on certain locations because of the favourable locational factors.

Several indices are used to identify the clustering of industries, important among them are:

- The number of industrial units

- Number of industrial workers

- Quantum of power used for industrial purposes

- Total industrial output, and

- Value added by manufacturing, etc.

Question 7.

Give a brief description of IISCO.

Answer:

IISCO stands for The Indian Iron and Steel Company.

- Factories under it: It sets up its first factory at Hirapur and later on another at Kulti. In 1937, the Steel Corporation of Bengal was constituted in association with IISCO and set up another iron and steel producing unit at Burnpur (West Bengal).

- Present Location: All the three plants under IISCO are located very close to Damodar valley coal fields (Raniganj, Jharia, and Ramgarh).

- Material: Iron ore comes from Singhbhum in Jharkhand. Water is obtained from the Barakar river, a tributary of the Damodar.

- Ownership: Steel production from IISCO fell considerably in 1972-73 and the plants were taken over by the government.

Question 8.

Why are most of sugar mills established in sugarcane producing areas?

OR

Why are the sugarcane industries located within the cane producing areas?

Answer:

Most of sugar mills are established in sugarcane producing areas because:

- Sugarcane is a weight-losing crop. The ratio of sugar’to sugarcane varies between 9 to 12 per cent depending on its variety. Its sucrose content begins to dry during haulage after it has been harvested from the field.

- Better recovery of sugar is dependent upon its being crushed within 24 hours of its harvesting.

Question 9.

Why iron and steel industry is located in peninsular plateau?

Answer:

Iron and steel plant requires raw materials which are weight losing, heavy & bulky therefore its location is influenced by: ‘

- Raw Materials: Iron ore, coal, limestone, dolomite, manganese are weight losing and therefore, industries should be located near the source of raw materials.

- Cost: Industry should be located at place where the cost of assembling and the raw material and distribution of finished product is the lowest. Some steel plants are located near coal fields and iron ore producing areas.

- Transport: All ’ the plants are located on the trunk rail routes which connects them to large urban market.All these conditions are favorable as peninsular India and hence iron and steel is locked there.

Question 10.

What are the factors affecting cotton textile industry?

OR

What favorable conditions are present in India for development of cotton industry?

OR

Give reasons for the development of cotton textile industries in India.

Answer:

The following favorable conditions are present in India for development of cotton industry:

- It is a tropical country and cotton is the most comfortable fabric for a hot and humid climate. So demand is high.

- Large quantity of cotton is grown in India.

- Abundant skilled labour required for this industry is available in this country.

- In some areas the people are producing cotton textiles for generations find transferred the skill from one generation to the other and in the process perfected their skills.

Question 11.

Why did the development of cotton textile industries occur in and around Mumbai?

Answer:

It was very close to the cotton producing areas of Maharashtra and Gujarat. Raw cotton used to be brought to Mumbai port to be transported to England. Therefore, cotton was available in Mumabi city itself. Mumbai was the financial centre and the capital needed to start an industry was available there. Employment opportunities attracted labour in large numbers. The machinery required for a cotton textile mill could be directly imported from England.

Question 12.

Give a brief account of cotton textile industry in India.

Answer:

- Tamil Nadu has the largest number of cotton mills.

- Coimbatore is the most important centre as approximately half the mills are located there.

- In Karnataka, the cotton textile industry has developed in the cotton producing areas in the north-eastern part of the state.

- In Andhra Pradesh, it is located in Telangana region where most of the mills are spinning mills producing yarn. Most important centres are Hyderabad, Secunderbad, Warangal and Guntur.

- In U.P., Kanpur is the largest centre. The important centres are Modinagar, Hathras, Saharanpur, Lucknow and Agra.

- West Bengal has centres like Howrah, Serampur, Kolkata and Shyarri nagar.

Question 13.

Cotton textile has been facing problem. Discuss.

Answer:

Cotton textiles has been facing tough competition from synthetic cloth due to the following reasons:

- Synthetic fibres’ inherent strength, durability, washability and resistance to shrinkage.

- Old and obsolete machinery are still operating leading to lesser output.

- Irregular power supply.

- Good quality growing areas went to West Pakistan.

- Per unit production is less.

Question 14.

State the importance of sugar industry in India.

Answer:

- It is the second most important agro-based industry in the country.

- It is the largest producer of sugarcane and contributes about 8 per cent of the total sugar production in the world.

- Beside khandsari and gur are also prepared from sugarcane.

- Industry provides employment for more than 4 lakhs persons directly and a large number of farmers indirectly.

Question 15.

What are petrochemical industries?

OR

Define petrochemical industries. Name four sub-groups of the products of these industries.

Answer:

Many items are derived from crude petroleum, which provide materials for many new industries, these are known as petrochemical industries.

Some groups of these industries:

- Polymers

- Synthetic fibres

- Elastomers

- Surfactant intermediate.

Question 16.

Name the three organisations working in petrochemical under the administration control of the department of chemical and petrochemicals.

Answer:

- Indian Petrochemical Corporation Limited (IPCL): It is responsible for the manufacturing and distribution of the various petrochemicals like polymers, chemicals, fibres and fibre intermediates.

- The Petrofils Cooperative Limited (PCL): A joint venture of government of India and Weaver’s Cooperative Society. It produces polyester filament yarn and nylon chips at its two plants located at Vadodara and Naldhari in Gujarat.

- Central Institute of Plastic Engineering and Technology (CIPET) imparts training in petrochemical industries.

Question 17.

What is the major impact of IT revolution in India?

Answer:

The information technology revolution opened up new possibilities of economic and social transformation.

- The IT and IT enabled business process outsourcing (ITES-BPO) services continue to be on a robust growth path.

- Indian software industry has emerged as one of the fastest growing sectors.

- Exports of the Indian software service sector which is approx 30.32% increase from previous year.

- The software industry has surpassed electronic hardware production.

- It provides international quality products.

- A majority of MNC’s operating in the area of information technology have either software development centres or

- A major impact of this growth has been on employment creation, which is almost doubled each year.

- Many software and technology parks have emerged which are training centres for various professions.

Question 18.

Compare between the textile and steel industries.

Answer:

Points of comparison:

- Both act as basic industries.

- Both cater to other industries. Cotton textile caters to hand loom, power loom whereas Iron and steel caters to mini plants, small scale, large scale, medium – and light industries.

- Both export their produces.

- Initially both started in private sector.

- Both are dependent on primary products.

Question 19.

What role do manufacturing industries play in development of an economy?

Answer:

Manufacturing industries provide employment to labour force. By the sale of their output, economy gets momentum. It provides base for the development of primary and tertiary sectors. Therefore, they act as barometer of economic development of a country.

Question 20.

Classify industries on the basis of the nature of manufactured products.

Answer:

On the basis of the nature of the manufactured products industries are of following types:

- Metallurgical industries

- Mechanical engineering industries

- Chemical and allied industries

- Textile industries

- Food processing industries

- Electricity generation

- Electronics

- Communication industries

Question 21.

What do you mean by Foot Loose industries? Give its features.

Answer:

Foot Loose Industries are those industries which are not dependent on any specific raw materials, for example, weight losing and other such thing. They depend on specific component parts which can be obtained anywhere.

- Such industries are generally non polluting.

- They produce in small quantity with small labour force.

- The important factor in their location is accessibility by road network.

- They can be located in a wide variety of places.

Question 22.

Name some integrated steel plants of India.

Answer:

Some of the integrated steel plants in India are:

- Tata Iron and Steel Company (TISCO)

- Indian Iron and Steel Company (IISCO)

- Visvesvaraiya Iron and Steel Works Ltd. (VISW)

- Rourkela Steel Plant

- Bhilai Steel Plant

- Durgapur Steel Plant

- Bokaro Steel Plant

Question 23.

Name some other steel plants of India other than integrated steel plants.

Answer:

Other steel plants:

- The Vizag Steel Plant, situated in Vishakhapatnam in Andhra Pradesh is the first port-based plant which started operating in 1992.

- The Vijaynagar Steel Plant at Hospet in Karnataka was developed using indigenous technology.

- The Salem Steel Plant in Tamil Nadu was commissioned in 1982.

Question 24.

Name the steel plants of India established in collaboration with a foreign country.

Answer:

The Rourkela Steel Plant was set up in 1959 in the Sundargarh district of Odisha in collaboration with Germany. The Bhilai Steel Plant was established with Russian collaboration in Durg District of Chhattisgarh and started production in 1959. Durgapur Steel Plant, in West Bengal, was set up in collaboration with the government of the United Kingdom and started production in 1962.

Bokaro Steel Plant was set up in 1964 at Bokaro with Russian collaboration

Long Answer Type Questions

Question 1.

Why most of the iron and steel industries are located in the Chhotanagpur plateau?

Answer:

This region extends over Jharkhand, northern Odisha and western West Bengal and is known for the heavy metallurgical industries.

This region owes its development to the discovery of coal in the Damodar Valley and metallic and non-metallic minerals in Jharkhand and northern Odisha. Proximity of coal, iron ore and other minerals facilitated the location of heavy industries in this region. Six large integrated iron and steel plants at Jamshedpur, Burnpur- Kulti, Durgapur, Bokaro and Rourkela are located within this region.

To meet the power requirement, thermal and hydroelectric plants have been constructed in the Damodar Valley. This region is well connected to the transportation network between the metros of Mumbai and Kolkata and water ways. Water for the plants is easily available from Subarnarekha and it’s tributary. Kolkata port is nearby. Densely populated surrounding regions provide cheap labour and Hugli region provides vast market for its industries. Heavy engineering, machine tools, fertilisers, cement, paper, locomotives and heavy electricals are some of the important industries in this region. Important centres are Ranchi, Dhanbad, Chaibasa, Sindri, Hazaribag, Jamshedpur, Bokaro, Rourkela, Durgapur, Asansol and Dalmianagar.

Question 2.

Explain different phases of development of cotton industry in India.

Answer:

The cotton textile industry is one of the traditional industries of India. In the ancient and the medieval times, it used to be only a cottage industry. India was famous worldwide for the production of muslin, a very fine variety of cotton cloth, calicos, chintz and other different varieties of fine cotton cloth.

Initially, the British did not encourage the development of the indigenous cotton textile industry. They exported raw cotton to their mills in Manchester and Liverpool and brought back instead the finished products to be sold in India. In 1854, the first modern cotton mill was established in Mumbai. Subsequently, two more mills, the Shahpur Mill and the Calico Mill were established in Ahmedabad. By 1947, the number of mills in India went up to 423 but the scenario changed after partition, and this industry suffered a major recession.

After independence India was left with 409 mills and only 29 per cent of the cotton producing areas. After Independence, this industry gradually recovered and eventually flourished. After 1921, with the development of the railway network other cotton textile centres expanded rapidly. In southern India, mills were set up at Coimbatore, Madurai and Bangalore. In Central India, Nagpur, Indore, Solapur and Vadodara became cotton textile centres. Cotton textile mills were set up at Kanpur based on local investment.

Tamil Nadu has the largest number of mills and most of them produce yarn rather than cloth. Coimbatore has emerged as the most important centre with nearly half the mills located there. Chennai, Madurai, Tirunelveli, Tuticorin, Thanjavur, Ramanathapuram and Salem are the other important centres. In Karnataka, the cotton textile industry has developed in the cotton producing areas in the north-eastern part of the state. Davangere, Hubli, Bellary, Mysore and Bangalore are important centres. In Andhra Pradesh, the cotton textile industry is located in the cotton producing Telangana region, where most of the mills are spinning mills producing yarn. The important centres are Hyderabad, Secunderabad, Warangal and Guntur. In Uttar Pradesh, Kanpur is the largest centre. Some of the other important centres are Modinagar, Hathras, Saharanpur, Agra and Lucknow. In West Bengal, the cotton mills are located in the Hugli region.

Question 3.

Explain different phases of development of petrochemical industry in India.

Answer:

Many items are derived from crude petroleum, which provide raw materials for many new industries, these are collectively known as petrochemical industries.

This group of industries is divided into four sub-groups:

- Polymers

- Synthetic fibres

- Elastomers

- Surfactant intermediate

Three organisations are working in the petrochemical sector under the administrative control of the Department of Chemicals and Petrochemicals.

- Indian Petrochemical Corporation Limited (IPCL) is a public sector undertaking. It is responsible for the manufacture and distribution of various petrochemicals like polymers, chemicals, fibres and fibre intermediates.

- Petrofils Cooperative Limited (PCL) is a joint venture of the Government of India and Weaver’s Cooperative Societies.

- Central Institute of Plastic Engineering and Technology (CIPET), involved in imparting training in petrochemical industry.

Polymers are made from ethylene and propylene. These materials are obtained in the process of refining crude oil. Polymers are used as raw materials in the plastic industry. The National Organic Chemicals Industries Limited (NOCIL), established in private sector in 1961, started the first naphtha based chemical industry in Mumbai. The plants located at Mumbai, Barauni, Mettur, Pimpri and Rishra are the major producers of plastic materials. Synthetic fibres are widely used in the manufacturing of fabrics because of their inherent’ strength, durability, washability, and resistance to shrinkage. Industries manufacturing nylon and polyester yarns are located at Kota, Pimpri, Mumbai, Modinagar, Pune, Ujjain, Nagpur and Udhna. Acrylic staple fibre is manufactured at Kota and Vadodara.

Question 4.

Write a detailed note on Hugli industrial area.

Answer:

It is located along the Hugli river.

Extension: This region extends from Bansberia in the north to Birlanagar in the south for a distance of about 100 km. Industries also have developed in Mednipur in the West Kolkata-Howrah from the nucleus of this industrial region.

Development: Historical, geographical, economic and political factors have contributed much to its development. It developed with the opening of river port on Hugli. Kolkata emerged as a leading centre of the country. Later, Kolkata was connected with interior parts by railway lines and road routes. Development of tea plantations in Assam and northern hills of West Bengal, the processing of indigo earlier and jute later coupled with the opening of coalfields of the Damodar Valley and iron ore deposits of the Chotanagpur plateau, contributed to the industrial development of the region.

Labour: Cheap labour available from thickly populated part of Bihar, eastern Uttar Pradesh and Odisha also contributed to its development. Kolkata, being the capital city of British India (1773-1911), attracted the British capital. The establishment of first jute mill at Rishra in 1855 ushered in the era of modern industrial clustering in this region. The major concentration of jute industry is at Haora and Bhatapara. The partition of the country in 1947 adversely affected this industrial region. Cotton textile industry also grew along with jute industry, paper, engineering, textile machinery, electrical, chemical, pharmaceuticals, fertiliser and petrochemical industries have also developed within this region. Factory of the Hindustan Motors Limited at Konnagar and diesel engine factory at Chittaranjan are landmarks of this region.

Location of petroleum refinery at Haldia has facilitated the development of a variety of industries.

Important industrial centres of this region: Kolkata, Haora, Haldia, Serampur, Rishra, Shibpur, Naihati, Kakinara, Shamnagar, Titagarh, Sodepur, Birlanagar, Bansberia, Belgurriah, Triveni, Hugli, Belur, etc.

Question 5.

What were the policies adopted under New Industrial Policy 1991? What were its objectives?

OR

Explain the objectives and measures initiated under new industrial policy announced in 1991.

Answer:

The new Industrial Policy was announced in 1991. Following measures were initiated under this policy:

- Abolition of industrial licensing,

- Free entry to foreign technology,

- Foreign investment policy,

- Access to capital market,

- Open trade,

- Abolition of phased manufacturing programme, and

- Liberalized industrial location progra¬mme.

The major objectives of this policy were as follows:

- Building on the gains already made,

- Correcting the distortions or weaknesses that have crept in,

- Maintaining a sustained growth in productivity and gainful employment and

- Last but not the least attaining inter¬national competitiveness.

Question 6.

Name the major areas where sugar industries are located?

OR

Name the major leading producing areas of sugar in India.

Answer:

Maharashtra has emerged as a leading sugar producing state in the country and produces more than one-third of the total production of the sugar in the country. Uttar Pradesh is the second largest producer of sugar. The sugar factories are concentrated in two belts – the Ganga- Yamuna doab and the Tarai region. The major sugar-producing centres in the Ganga-Yamuna doab are Saharanpur, Muzaffarnagar, Meerut, Ghaziabad, Baghpat and Bulandshahr districts; while Kheri Lakhimpur, Basti, Gonda, Gorakhpur, Bahraich are important sugar producing districts in the Tarai region. In Tamil Nadu, sugar factories are located in Coimbatore, Vellore, Tiruvanamalai, Villupuram and Tiruchchirappalli districts. Belgaum, Bellary, Mandya, Shimoga, Bijapur, and Chitradurg districts are the major producers in Karnataka.

The industry is distributed in the coastal regions, i.e. East Godavari, West Godavari, Vishakhapatnam districts and Nizamabad, and Medak districts of Telangana alongwith Chittoor district of Rayalseema.

The other states which produce sugar are Bihar, Punjab, Haryana, Madhya Pradesh and Gujarat. Saran, Champaran, Muzaffarnagar, Siwan, Darbhanga, and Gaya are the important sugarcane producing districts in Bihar.

Question 7.

Distinguish between textile industry & Steel industry.

Answer:

Textile Industry | Steel Industry |

(i) It is an agro based industry | (i) It is mineral based industry. |

(ii) It employs larger number of people. | (ii) It employs lesser number of people. |

(iii) The capital investment is comparatively less. Most of them are under private sector. | (iii) The capital investment is very heavy and the dividends come late. Therefore majority of them are under public sector. |

(iv) They are highly decentralized. | (iv) They are mostly centralized and integrated, though mini steel plants are coming up. |

(v) It is a consumer and a basic industry. | (v) It is a basic or key industry. |

Higher Order Thinking Skills (HOTS)

Question 1.

Globalisation has widened the gap between the developed and developing states of India. Justify the statement.

Answer:

It is rightly said that globalisation has widened the gap between the developed and developing states of India.

- Major share of both domestic investment as well as foreign direct investment went to developed states. Example; Out of the total proposed investment by the industrial entrepreneurs during 1991 – 2000, 23% was for Maharashtra, 17% for Gujarat, 7% for Andhra Pradesh, 6% for Tamil Nadu while Uttar Pradesh had only 8%.

- Inspite of several concessions, seven north eastern states could get less than 1% of the proposed investment.

- Economically weaker states could not compete with the developed states in open market in attracting industrial investment proposals.

Question 2.

How does FDI benefit the economy?

Answer:

Foreign Direct Investment (FDI) has been seen as a supplement to the domestic investment for achieving higher level of economic development. FDI benefits the domestic industry as well as the consumers by providing technological upgradation, access to global managerial skills and practices, optimum use of natural and human resources, etc.

Question 3.

“Iron and Steel industry is called a basic and heavy and industry”. Why? Explain.

Answer:

“Iron and steel industry is called a basic industry due to the following reasons:

- The industry forms a base for all other industries.

- No industry can be imagined that does not make use of iron and steel in one form or the other.

- The industry lays the foundation of rapid development of all other sectors in the economy – agriculture, etc.

It is a heavy industry because of the following reasons:

- Its raw materials are bulky.

- Other minerals used like limestone; manganese, etc. are also bulky.

- Coal used as source of power in blast furnaces is also bulky.

- And finally its finished products are also bulky.

Question 4.

Discuss the various locational advantages of iron and steel industry in Jamshedpur.

Answer:

Jamshedpur has many locational advantages for iron and steel industry:

- Iron ore is obtained from Noamundi and Badam Pahar.

- Coal is obtained from Joda mines in Odisha.

- Water is obtained from Subernarekha and Kharkai rivers.

- Very close to Mumbai – Kolkata railway line and about 240 km away from Kolkata which is the nearest port for the export of steel.

- Coking coal obtained from Jharia and West Bokaro coal fields.

Question 5.

Availability of labour is the biggest cause for development of Hugli industrial region. Justify.

Answer:

Cheap labour available from thickly populated parts of Bihar, eastern Uttar Pradesh and Odisha also contributed to its development. Kolkata, being the capital city of British India (1773-1911), attracted British capital. The establishment of first jute mill at Rishra in 1855 ushered in the era of modern industrial clustering in this region. The major concentration of jute industry is at Haora and Bhatapara. The partition of the country in 1947 adversely affected this industrial region. Cotton textile industry also grew along with jute industry, paper, engineering, textile machinery, electrical, chemical, pharmaceuticals, fertilisers and petrochemical industries have also developed within this region. Factory of the Hindustan Motors Limited at Konnagar and diesel engine factory at Chittaranjan are landmarks of this region. Location of petroleum refinery at Haldia has facilitated the development of a variety of industries.

Map Based Questions

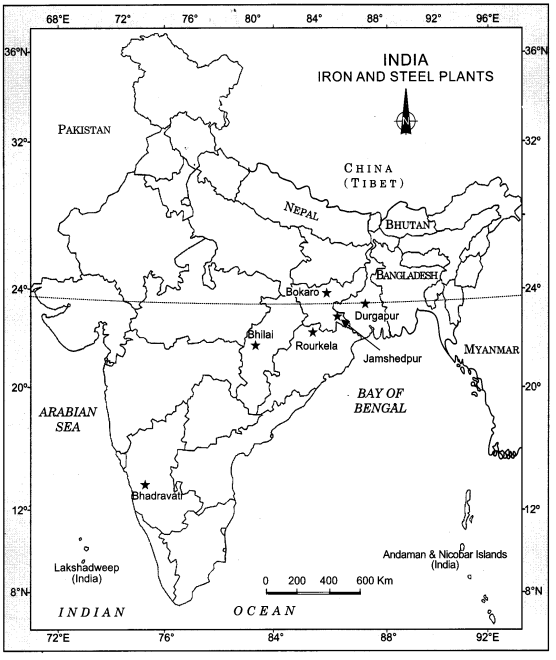

Question 1.

Label and locate the following on physical map of India.

Iron and steel plants — Bhadravati, Bhilai, Bokaro, Durgapur, Rourkela and Jamshedpur.

Answer:

Question 2.

Label and locate the following on physical map of India.

Cotton textiles centres — Ahmedabad, Surat, Gwalior, Varanasi, Murshidabad, Pune, Nagpur, Solapur and Mysore.

Answer:

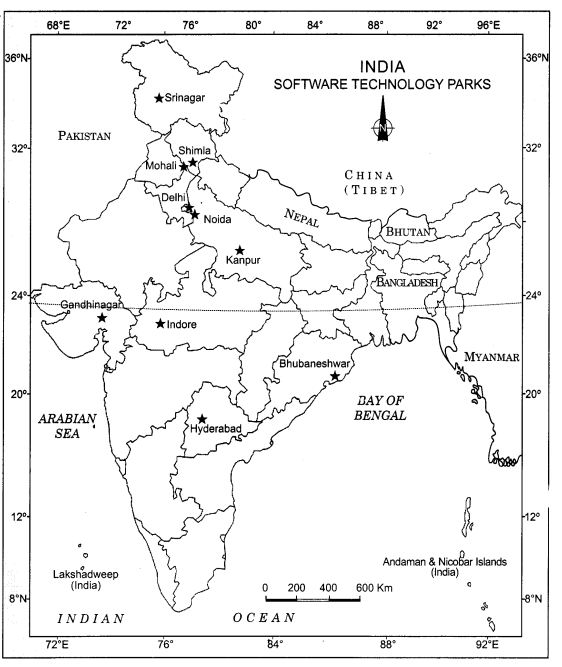

Question 3.

Label and locate the following on physical map of India.

Software technology park — Gandhinagar, Srinagar, Mohali, Shimla, Delhi, Noida, Kanpur, Indore, Hyderabad, Bhubaneshwar.

Answer:

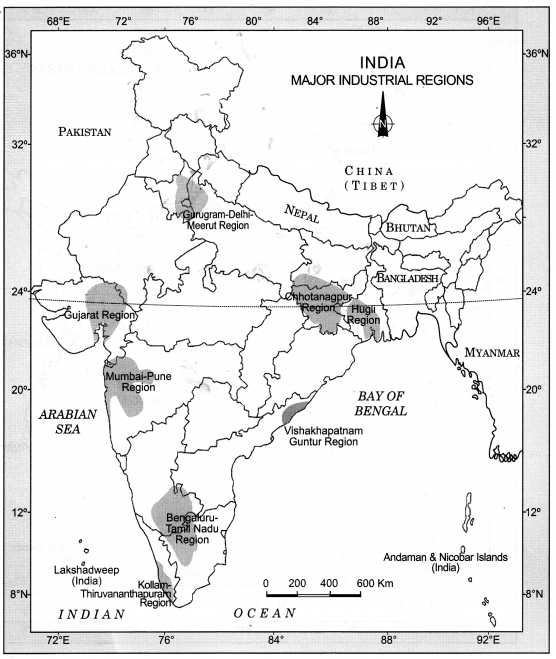

Question 4.

Label and locate the following on physical map of India.

Important industrial regions — Gurgaon-Delhi-Meerut region, Chhotanagpur region, Mumbai-Pune Region, Bangalore-Tamil Nadu region, Gujarat region, Hugli region, Kollam Thiruvananthapuram region, Vishakhapatnam Guntur.

Answer:

Important Questions

Very Short Answer Type Questions:

Question 1.

What was the main reason for establishing the first cotton textile mill in Mumbai? (A.I. 2010)

Answer:

It was very close to cotton producing areas.

Question 2.

Name the iron and steel plant located in Chhattisgarh. (A.I. 2010)

Answer:

Bhilai steel plant.

Question 3.

Which is the largest sugar producing state of India? (A.I. 2010)

Answer:

Maharashtra.

Question 4.

Which state of India has the largest number of cotton mills? (Delhi 2011)

Answer:

Tamil Nadu.

Question 5.

Name the two rivers that provide water to Tata Iron and Steel Company (TISCO). (Delhi 2013)

Answer:

- Subarnarekha

- Kharkai.

Question 6.

“Why is the large integrated steel industry located close to the source of raw material?” (Delhi 2016)

Answer:

Because the raw materials such as limestone, dolomite, manganese, etc., for these industries are weight losing and heavy.

Question 7.

Explain one reason for the import of petroleum and its products is large quantities in India. (A.I. 2016)

Answer:

- Production of petroleum and its products is less than requirement in India.

- Demands is increasing due to regular increase in population.

- Rising industrialization

- Better standard of living.

Question 8.

Mention any two factors responsible for the establishment of cotton textile mills in Mumbai. (Delhi 2018)

Answer:

Factors responsible for establishment of cotton textile mills in Mumbai:

- Close proximity to the cotton producing areas of Gujarat and Maharashtra.

- Humid climate

- It was the financial centre and had the capital needed to start an industry.

- Transport facilities

- Cheap and abundant labour

- Port facilities at Mumbai

- Availability of hydro-electricity (Any two)

Short Answer Type Questions:

Question 1.

Name the three leading cotton textile producing states of India and also state the most important centre of this industry in each of these states. (CBSE 2004, 06)

Answer:

Tamil Nadu, Maharashtra and Western Uttar Pradesh are the three main cotton textile producing states in India.

The three main centers of cotton industry in above states are:

- Tamil Nadu : Madurai, Coimbatore

- Maharashtra : Mumbai

- Uttar Pradesh : Kanpur

Question 2.

Explain the role of ‘Market’ and Transport’ in the location of industries in India. (Delhi 2013)

Answer:

Markets provide the outlets for manufactured products. Heavy machines, machine tools, heavy chemicals are located near the high demand areas as these are market oriented. Cotton textile industry is generally located in large urban centres. Petroleum refineries are also located near the markets is the transport of crude oil is easier and several products derived from them are used as raw materials in other industries. Transport: Development of any industry is very much depends on good means of transport. All the production is meant for consumption from the fields and factories, the produces is brought to the place from where consumers purchase it. With the result all industries are well linked with roads, railways or seaways main industries are directly liniked with rail routes.

Question 3.

Explain the role of ‘power’ and ‘raw material’ in the location of heavy industries in India. (Delhi 2013)

Answer:

Power

- It provides the motive force for machines.

- Its supply has to be ensured before the location of any industry.

- Certain industries, like aluminium and synthetic nitrogen manufacturing industries tend to be located near sources of power.

- Such industries are power intensive and require huge quantum of electricity.

Raw Materials:

- Industries using weight losing raw materials are located in the regions where raw material sources.

- Sugar mills, pulp industries, copper smelting and pig iron industry are located near their raw material sources.

- Most of the iron and steel industries are located either near coal fields or near sources of iron ore.

Question 4.

Explain any three locational factors which helped in the development of ‘Gujarat Industrial Region’. (A.l. 2013)

Answer:

- The region lies between Ahmedabad and Vadodara. Its development is associated with the location of the cotton textile industry.

- This region became an important textile region.

- Located in cotton growing area, this region has double advantage of the proximity of raw materials as well as of market.

- This discovery of oil fields led to the establishment of petrochemical industries around Ankleshwar, Vadodara and Jamnagar.

Question 5.

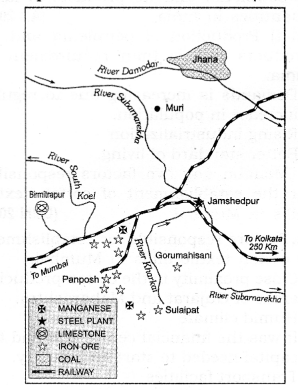

Study the following diagram and answer the questions that follow: (Delhi 2016)

(i) Identify and name the steel plant shown in this diagram.

(ii) Name the mining fields which supply coal and limestone to this plant.

(iii) Mention the source of water for this plant.

Answer:

(i) Tata Iron and Steel Plant (TISCO).

(ii) Coal comes from Jharia coal fields and limestone comes from Birmitrapur.

(iii) Source of water:

- Subarnarekha River

- Kharkai River

Question 6.

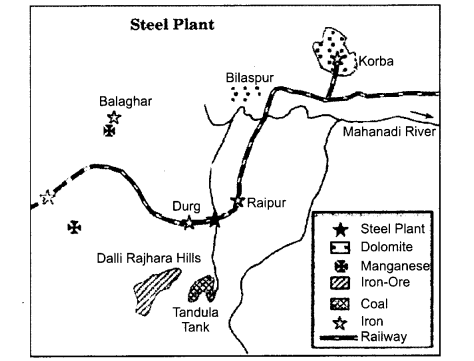

Study the diagram given below and answer the questions that follow: (A.I. 2017)

Question 6.(i)

Identify and name the steel plant given above. In which State is this plant located?

Answer:

Bhilai Steel plant

State: Chhattisgarh

Question 6.(2)

Which is the main source of power for this steel plant? Which rail route provides transport facilities to this plant ?

Answer:

Main source of power – Korba Thermal power station.

Rail route – Kolkata – Mumbai rail route

Question 6.(3)

What are the major sources of iron-ore and water for this steel plant?

Answer:

Iron ore : Dalli – Rajhara mine.

Water: Tandula tank/dam

Major factors responsible for establishment of Tata Iron & Steel industry in Jamshedpur:

- It lies very close to the Mumbai – Kolkata railway line.

- Kolkata is the nearest port for the export of steel about 240 km away.

- The rivers Subanarekha and Kharkai provide water to the plant.

- Iron ore is obtained from Noamundi and Badam Pahar.

- Coal is brought from Joda mines in Orissa.

- Coking Coal comes from Jharia and West Bokaro coalfields.

-

Any other relevant point.

(Any three points to be explained

Long Answer Type Questions:

Question 1.

Explain with examples any five geographical factors that affect localisation of an industry at a particular place in India. (A.I. 2011)

Answer:

Location of industries is influenced by several factors like access to raw materials, water supply, climate, soil, minerals power, market, capital, transport and labour, etc. Some of them are:

- Raw materials: Industries using weight losing raw materials are located in the regions where raw materials are located. Example; most of the iron and steel industries are located either near coalfields (Bokaro, Durgapur, etc.) or near sources of iron ore (Bhadravati, Bhilai, and Rourkela).

- Power: Power provides the motive force for machines, certain industries, like aluminium and synthetic nitrogen manufacturing, industries tend to be located near sources of power because they are power intensive and require huge quantum of electricity.

- Market: Markets provide the outlets for manufactured products. Cotton textile industry uses a non-weight-losing raw material and is generally located in large urban centre, example; Mumbai, Ahmedabad, Surat, etc. Petroleum refineries are also located near the markets as the transport of crude oil. Koyali, Mathura and Barauni refineries are typical examples.

- Transport: Industries are concentrated in Mumbai, Chennai, Delhi and in and around Kolkata. The industries shifted to interior locations, only when railway lines were laid.

- Labour: In India, labour is quite mobile and is available in large numbers due to our large population. Example; cheap labour available from thickly populated part of Bihar, eastern U.P. and Orissa contributed to the development of Hugli Industrial region.

Question 2.

State five features each of Gujarat industrial region and chhotanagpur industrial region. (2004, 06, 08, 12, 13, 14)

Answer:

The five features of the following industrial regions are:

Gujarat Industrial Region:

- The nucleus of this region lies between Ahmadabad and Vadodara, though this region extends upto Valsad and Surat in the South.

- The development of this industrial region is mainly due to the cotton textile industry since 1860.

- After the decline of cotton textile from the Mumbai region the region has double advantage of the proximity of raw material and market.

- The discovery of oilfields led to the development of a variety of petrochemical industries in Ankleshwar, Vadodara and Jamnagar.

- Petroleum refinery at Koyali provided raw materials to a host of petrochemical industries.

Chotanagpur Industrial Region: This industrial regions extends over Jharkhand, northern Orissa, and western West-Bengal.

- This region owes its development to the discovery of coal in the Damodar valley and metallic nonmetallic minerals in Jharkhand and northern Orissa.

- Jamshedpur, Burnpur-Kulti, Durgapur, Bokaro and Rourkela are the prominent integrated iron and steel industry region.

- Power requirement is fulfilled by thermal and hydro electric plants constructed on the Damodar river.

- The densely surrounding region of Bihar, West Bengal, and Orissa provide unskilled and skilled labour force on large scale.

Question 3.

Why do large scale industries choose different locations? Explain any four factors which influence the industrial location. (Delhi 2017)

Answer:

Large scale industries choose different locations due to:

Industries maximize profits by reducing costs. Therefore, industries should be located at points where cost of production is lowest.

Factors influencing industrial location:

- Supply of raw materials

- Access to market

- Availability of labour

- Sources of energy

-

Access to transportation and communication

(Any four factors to be explained)

Question 4.

Mention any four major objectives of the New Industrial Policy, 1991 of India. Describe the role of globalisation in achieving these objectives. (A.I. 2017)

Answer:

Major objectives of the New Industrial Policy 1991

- To build on the gains already made

- Correct the distortions or weakness that have crept in.

- Maintain a sustained growth in productivity.

- Gainful employment and attain international competitiveness.

Role of Globalisation:

- Increase in Foreign Investment,

- Availability of Foreign Technology,

- Open Trade Policy,

-

International competition for better products,

(Any three points to be explained)